Just How to Accomplish Ideal Foam Control for Improved Manufacturing Effectiveness

Just How to Accomplish Ideal Foam Control for Improved Manufacturing Effectiveness

Blog Article

Reliable Techniques for Accomplishing Optimum Foam Control in Chemical Manufacturing

Efficient foam control is a critical aspect of chemical manufacturing that can considerably affect production effectiveness and product quality. By comprehending the mechanisms of foam formation and selecting proper anti-foaming representatives, makers can take proactive procedures to alleviate excessive foam.

Understanding Foam Development

Surfactants, or surface-active agents, reduce the surface area stress of the fluid, helping with bubble stability and advertising foam generation. In addition, frustration or blending procedures can boost bubble development, usually aggravating foam concerns. The features of the liquid tool, including thickness and density, additional influence foam actions; as an example, more thick fluids often tend to catch air better, causing increased foam security.

Understanding these basic facets of foam formation is essential for effective foam control in chemical manufacturing. By identifying the conditions that advertise foam development, makers can implement targeted techniques to mitigate its adverse results, consequently enhancing production procedures and making certain consistent product quality. This fundamental understanding is vital prior to checking out specific approaches for managing foam in commercial settings.

Selection of Anti-Foaming Representatives

When picking anti-foaming agents, it is necessary to take into consideration the particular features of the chemical procedure and the kind of foam being generated (Foam Control). Various elements affect the performance of an anti-foaming representative, including its chemical composition, temperature level security, and compatibility with various other process products

Silicone-based anti-foams are commonly utilized as a result of their high efficiency and wide temperature level array. They work by lowering surface area stress, allowing the foam bubbles to coalesce and damage even more quickly. They may not be suitable for all applications, particularly those involving delicate formulas where silicone contamination is a worry.

On the other hand, non-silicone agents, such as mineral oils or natural substances, can be useful in details situations, particularly when silicone residues are unwanted. These agents often tend to be less efficient at greater temperatures yet can offer effective foam control in other problems.

Additionally, understanding the foam's beginning-- whether it arises from aeration, agitation, or chain reactions-- guides the choice procedure. Testing under real operating conditions is important to make certain that the chosen anti-foaming agent satisfies the distinct requirements of the chemical production process properly.

Refine Optimization Techniques

Reliable foam control is an essential aspect of enhancing chemical production processes. To improve effectiveness and lessen manufacturing expenses, manufacturers have to implement targeted process optimization techniques. One important technique involves changing mixing speeds and configurations. By fine-tuning these specifications, operators can minimize turbulence, thus reducing foam development throughout blending.

Additionally, managing temperature level and stress within the system can significantly influence foam generation. Reducing the temperature visit the site level may reduce the volatility of particular parts, causing reduced foam. Keeping optimal pressure levels assists in mitigating extreme gas release, which adds to foam stability.

One more reliable technique is the critical addition of anti-foaming representatives at critical points of the procedure. Mindful timing and dosage can make sure that these agents successfully reduce foam without disrupting other procedure criteria.

Additionally, including a systematic assessment of basic material residential or commercial properties can aid determine inherently frothing substances, permitting preemptive measures. Carrying out regular audits and procedure testimonials can reveal inadequacies and areas for renovation, making it possible for continuous optimization of foam control approaches.

Monitoring and Control Solution

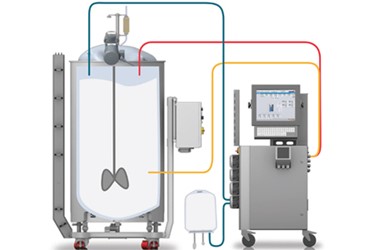

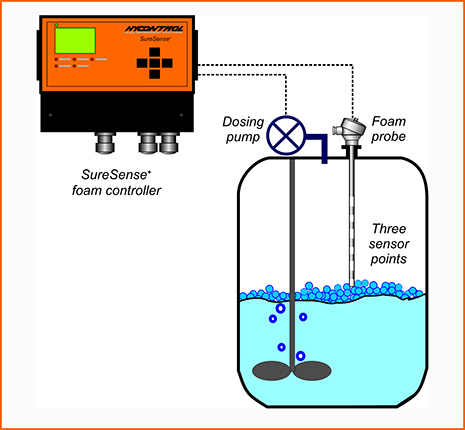

Tracking and control systems play a critical function in keeping optimum foam administration throughout the chemical manufacturing process. These systems are important for real-time monitoring and adjustment of foam levels, making sure that manufacturing effectiveness is made best use of while minimizing disruptions triggered by excessive foam formation.

Advanced sensing units and instrumentation are used to find foam density and height, supplying vital information that notifies control algorithms. This data-driven technique permits the prompt application of antifoaming agents, making certain that foam degrees stay within appropriate limitations. By integrating surveillance systems with procedure control software application, makers can carry out automated feedbacks to foam fluctuations, decreasing the requirement for manual treatment and boosting functional uniformity.

Additionally, the combination of artificial intelligence and anticipating analytics into keeping an eye on systems can facilitate aggressive foam management. By analyzing historical foam information and functional criteria, these systems can anticipate foam generation patterns and recommend preemptive procedures. Normal calibration and maintenance of tracking tools are important to guarantee accuracy and integrity in foam discovery.

Ultimately, efficient surveillance and control systems are important for maximizing foam control, advertising security, and improving overall performance in chemical web link production settings.

Study and Finest Practices

Real-world applications of monitoring and control systems highlight the significance of foam monitoring in chemical production. A notable instance research study involves a Recommended Site massive pharmaceutical producer that carried out an automated foam discovery system.

An additional excellent case comes from a petrochemical company that took on a mix of antifoam agents and procedure optimization techniques. By examining foam generation patterns, the organization customized its antifoam dosage, leading to a 25% reduction in chemical use and considerable expense financial savings. This targeted technique not only minimized foam disturbance but also boosted the general security of the manufacturing process.

Final Thought

Finally, achieving optimal foam control in chemical production demands a thorough strategy including the selection of appropriate anti-foaming representatives, application of procedure optimization strategies, and the combination of advanced monitoring systems. Routine audits and training even more enhance the efficiency of these techniques, fostering a culture of continuous improvement. By resolving foam development proactively, manufacturers can substantially boost manufacturing effectiveness and item high quality, eventually adding to more cost-effective and sustainable operations.

By comprehending the systems of foam development and picking ideal anti-foaming representatives, manufacturers can take positive steps to mitigate excessive foam. The characteristics of the liquid tool, including thickness and density, further influence foam behavior; for example, even more thick liquids often tend to catch air more efficiently, leading to increased foam security.

Comprehending these essential aspects of foam formation is crucial for effective foam control in chemical production. By evaluating historic foam data and operational criteria, these systems can anticipate foam generation patterns and recommend preemptive procedures. Foam Control. Normal audits of foam control gauges make certain that procedures remain optimized, while cultivating a culture of positive foam monitoring can lead to lasting renovations throughout the production spectrum

Report this page